It's been quite a while since I've had opportunity to mill any timber, in fact possibly more than a year. It basically just comes down to timing. That and being a sole operator means that sometimes you just can't arrange to fit everything into a working week, month or indeed the year.

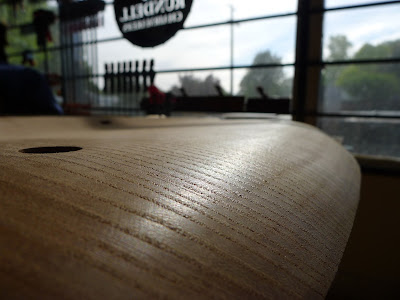

This is the smallest of the 4 Western Yellow Pines.

And so it's fantastic to bring the Timberking Sawmill up to Pineville and finally start to wade through the pile of logs I've had sitting here for far too long, including an enormous Western Yellow Pine ( in four sections ), a huge Stone Pine , a couple of good Californian Redwoods and a couple of little Ash and Oak logs.

The sawmill performed flawlessly, but as I've explained to a few people who come to have a look at it working, it does require a lot of concentration. Although it is entirely hydraulically controlled, there are no mechanisms in place to stop you from getting into serious trouble if you are not watching what you are doing. For instance if the log loading arms are not lowered after lifting a log onto the cutting deck, the saw head will plough straight into them. Similarly the blade will hit and damage the log supports if they are not lowering beneath the trajectory of the blade.

The blade will hit those orange log stops on the left of the log if you're not paying attention

Thankfully none of the above occurred, but I have to admit a momentary lapse of concentration at one point made me come close.

On the subject of logs and sawn timber, I often find myself being asked about the value of a sawlog, whether standing or on the ground. It's understandable that the question arises, when you see the price of sawn specialty timber/lumber in a retail yard. Using 50mm ( 2" or 8/4 ) thick stock as a yardstick, some U.S. species such as Hard Maple and Black Walnut can be over $5000 per cubic metre ( or about $12 a board foot ) here in Melbourne. So often when people see a big old Oak tree standing in the paddock they suddenly think there's a $5000+ paycheque coming their way. Unfortunately for them, it's not the case.

If this is growing in your backyard please let me know……

Unless you have somehow managed to have a 2000 year old Huon Pine standing dead next to the backyard woodshed, or that annoying 40' tall Brazilian Rosewood that just has to be cut down as it's threatening to fall on the chook house, then I'm afraid if your asking me, I'll tell you there's no money going to be exchanged for your tree or log. It's just not feasible. In fact I would be far better off driving that hour and a half to the timber yard and paying that $5000+ per cube than driving to that paddock to collect the log. It's all in the logistics.

I salvaged these fallen Elms in Kyneton in 2011. A little large to just throw over your shoulder

For starters collecting a log can be difficult enough in the first place, especially a big one. Unless there's heavy machinery such as a backhoe or excavator handy, it usually means hiring expensive crane trucks.

Expensive

Once collected you then need a place to store it until it's ready to be milled, not always as easy as it sounds unless you are lucky enough to have easily accessible land. Then comes the milling. Portable Mills are realistically the only method of milling furniture type logs these days with the rapid demise of our logging industry and permanent sawmills. Portable mills do not come cheaply either and whether you have one at your disposal or you're hiring one with an operator, it is a costly exercise.

Without this front end loader ( or a crane ), moving logs like this would be impossible

Then comes milling the log. Again some form of machinery is necessary to manoeuvre the log to the mill. After it has been sawn it's important that the sawn timber is brushed down and stacked as soon as possible. A dry wooden spacer, known as a 'sticker' in most camps, is placed about every 300mm ( 12" ) or closer along the length of the board and then the next board placed carefully on top. The 'stickers' themselves have to be all the same dimension and you'll need a large amount of them too, which is why I value the pile I have almost as much as the timber sitting on them.

Strap 'em up

Once the timber is all carefully stacked and stickered it should be strapped up tight or at least a heavy weight placed on top to help minimise any movement during drying. The stack then needs to be moved and stored in a cool, still and dry location.

This Elm won't stay dead straight for long if its not stacked and stored right.

Contrary to popular belief, it's not just direct sunlight/heat or rain that can have an adverse effect on some timbers drying evenly. Howling wind can also be just as detrimental to freshly sawn timber, especially with timber notorious for twisting and wracking, such as English Elm.

Then it's a case of hurry up and wait. Most dense hardwoods should be left to dry ( naturally as opposed to kiln ) for at least one year per 25mm ( 1" ). So those Lovely Elm boards above, sawn at 55mm, should be looking good around January......2018.

I'll just shove it under the mattress….

Storing large piles of sawn timber, undercover takes up a lot of real estate too. Saw 10 or so good sized logs like I just have and you'll see just how much.

And lastly the yield. A high production permanent sawmill of old will often yield only as little as 25% of the logs original volume. While portable bandsaw type mills can increase this recovery dramatically, it still means a hell of a lot of the log ends up as sawdust or waste from the outset.

So the upshot of the whole deal is that often if I'm asked whether I am interested in salvaging a log I will assess it with a pretty critical eye in the first place. With all of the above, you can understand that it has to be worthwhile. If it's worthwhile I then check that the person who has it is not looking for me to contribute to their hasty retirement fund. And lastly if it is indeed a substantial log or special old tree, I'll more often than not offer to make a small item from it, for them as a thank you. There are a few 3 legged milking stools around the countryside that are testimony to that.

Hello there Mr. Sequoia !

So as you can imagine that big old Oak tree isn't looking quite so desirable any more, but despite all of the above, I still get a bit of a buzz when I mill a great log. Flipping over a freshly sawn board and seeing stunning figured timber staring back at you, never gets old. Waiting patiently until 2018 sure does though....