After teaching a lot for the past month or so, it's been a true liberation to get back into the workshop and get a chance to make something myself. A chair of course.

The spindles should look like they have grown out of the seat.

The Crested Rocker from the previous post has been just the ticket too. A slightly more complex chair than the Fanbacks, Sackbacks and Continuous Arm Chairs I've been making of late. But this time around there has been a few factors that have made this a surprisingly quick build so far.

One is that I've made a fair few of them now, so the joinery is more familiar. The second is that I have used air dried timber for the steam bends as opposed to the green or fresh Oak I would normally utilise.

This means that the bends set surprisingly quickly, have minimal spring back and virtually no shrinkage. It's a big time saver when a chair part doesn't have to spend days on end, drying in a heat box or kiln. Especially with parts the size of the stiles or back posts, which are 38mm ( 1 1/2 " ) octagons . That's a large part to dry when its green.

This means that the bends set surprisingly quickly, have minimal spring back and virtually no shrinkage. It's a big time saver when a chair part doesn't have to spend days on end, drying in a heat box or kiln. Especially with parts the size of the stiles or back posts, which are 38mm ( 1 1/2 " ) octagons . That's a large part to dry when its green.

Lastly I used a little jig that I recently built a dozen of, for a Barstool class. Quite simply it locates an indicator pin in the correct plane to sight off for drilling stretcher mortises. The jig is usually attached to the leg, but in this case I used it to align the drilling angle of the stepped mortise into the stile from the arm post. I've always found drilling this mortise to be trickiest part of making the chair. This is due to the drilling angle being acute to the seat and on a curved chair part. But the angle jig made the process a no brainer. Every angle that needed to be known or referenced was right there on the little pin.

The resulting joint was the best I've done on a chair of this kind, full stop.

So Friday I fitted the spindles to both the seat and crest, turned the stretchers, roughed out the rockers and carved the seat. I mentioned in the last post that I was careful to choose 1/4 sawn Elm for this chair.

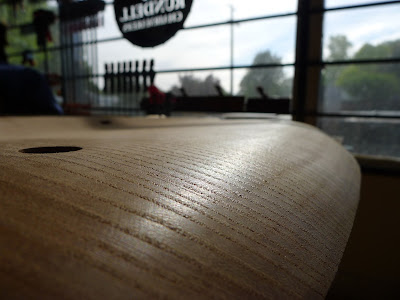

Rift or back sawn Elm, although visually stunning as a finished seat, can often be a real pain to carve. The porosity of the radial growth rings is the issue here. When shaved or scraped at the slight angles found at the front of most Windsor chair seats, the wide cross sections of porous growth rings can fracture and crumble, making final smoothing problematic. In difference, shaving those same ring porous growth rings on their edge results in a clean, firm surface without those issues.

I think the photo above speaks for itself. The front edge of the seat was spokeshaved across its width and scraped briefly. A light sand with 240 paper and final scraping will reveal a beautiful finished seat, after the entire chair is assembled.

Yesterday we had the pleasure of Master Cooper George Smithwick's company in the workshop, to teach the Coopered Wooden Bucket Class. The four students kept up the tradition of travelling to the workshop from far and wide. Ray travelled from Thalloo in Central Gippsland, Rosemary, from Waubra, half way between Ballarat and Avoca, Nick from Melbourne and Drew from Bendigo. I'm very fortunate to have a workshop that people gravitate to, to take part in these classes. As the saying goes, love what you do and you'll never work a day in your life.

The day went as smooth as silk and thanks to George's great teaching skills and the great work of the students, we kept our 100% success rate of no leaking buckets too. Nice work. Our tradition of filling the new buckets with water and holding them over the makers head, may have contributed to their determination to make one that didn't leak….

I'm pretty happy to be planning out the remainder of the year. Aside from another 3 classes, I'm planning to bring the sawmill up to Pineville to mill an ever increasing pile of logs in the paddock. That should yield some spectacular Redwood, Yellow Pine, Hoop Pine and Blackwood. And if I'm lucky, perhaps an Osage Orange log to mill also..... stay tuned.